Before I get started, I just have to say how overwhelmed I was by the outpouring of encouragement from my last post… Straight From The Heart. Seriously, I am grateful to have such awesome readers and friends in my life. All of the love and support has given me the motivation and courage to start writing the next one. I’m scared but excited!!

Sooo.... Just a heads up…This post is photo heavy. And if you aren't really interested in how I did this little job, scroll down to the bottom for a little surprise. :)

Back in November, if you remember I did a giveaway for a light fixture and I in turn, received one.

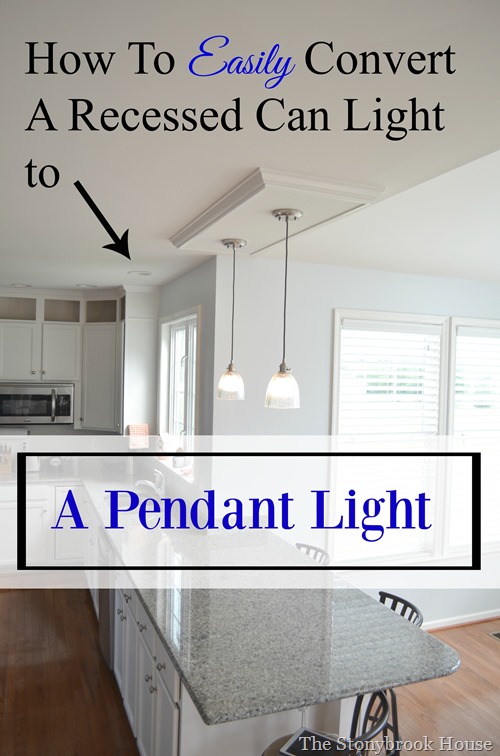

Yet, I never showed you how I turned a recessed can light into a pendant light. You probably didn’t even realize that there wasn’t a pendant hanging there before. Scroll back to the top and you'll see it. :) If you're interested you can see how we installed our matching pendant lights, the builder put them in the wrong place and we corrected that.

So, I’m here to show you that it can be easily done. I am not a professional, or an electrician, so please understand that if you try this, you are doing it at your own risk. In fact, I was a bit nervous working with wiring and such, but Hubby was away and I needed to get this fixture up! Turns out, it wasn't hard at all!

I went to Home Depot and picked up this conversion kit. It was relatively inexpensive, under $20.

(This is an affiliate link. I only recommend products or services I use personally and believe will be good for my readers.)

This kit is also available on Amazon,Westinghouse Recessed Light Converter

This kit is also available on Amazon,Westinghouse Recessed Light Converter

Here's what was in the kit. A screw in “pig-tail”, a 2-part brace with screws, a metal plate and the face plate. It will also help to read the instructions included. :)

Looks pretty straight forward. I also watched this You Tube Video a couple of times. The more help the better!!

First, make sure that the power is off to this light. That is the MOST important thing to do!! Then unscrew the lightbulb.

To remove the can light sleeve, you must squeeze the pins next to the socket.

Then it should easily come out.

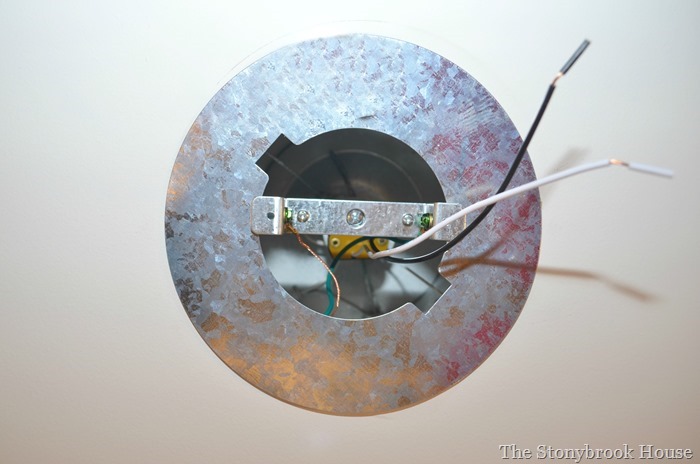

This is the can light with the sleeve removed.

Next, screw the “socket pig-tail” into the light socket. Fairly simple so far!

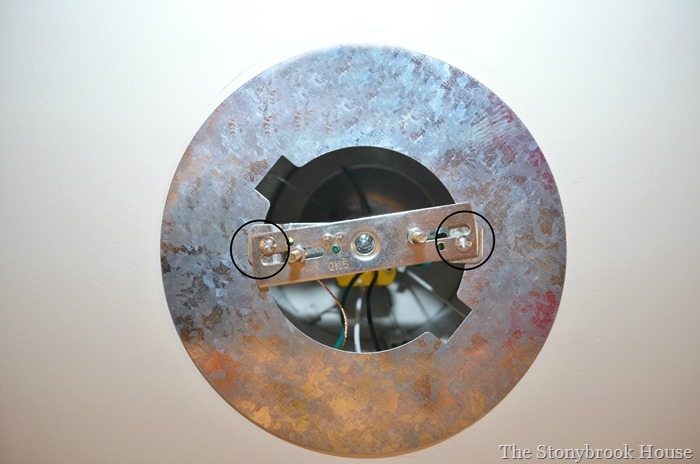

Find the brace, you will need to separate the bracket from the brace by removing the two screws. There is a washer under one screw, don't lose it.

Loosen the center screw so that you can slide the bracket open to fit the width of the can. Then tighten and secure the center screw.

The brace needs to be secured with screws at each end. This was probably the toughest part for me. The screws would not go through the metal. I ended up drilling a hole for each screw to attach the brace to the can light insert.

Next, you will need the second part of the brace that has the grounding wires attached to it. It is attached with two screws provided, don't for get the washer. It goes back together just the way you took it apart.

There are 2 wires on this brace attachment, a green wrapped wire and a copper wire. The green wire has one end attached to the brace, and the other end needs to be clipped to the edge of the can light, then secured with a screw provided. The copper wire will be connected to the light fixture. I'll show you that later.

Now for the metal plate, align the plate with the bracket, then twist. It should stay in place.

The light fixture should come with a mounting bracket. Some light fixtures have these bolts mounted in place. Mine weren't, I needed to make sure that these bolts were in the correct spot to line up with the light fixture face plate. They will peek through it, so you can screw on the little knobs.

Once that’s done, you will secure it to the brace on the conversion kit, with two screws.

Now we are ready to for the light fixture wires. But first make sure you have the decorative white face plate fed through before you fish the wires through the bracket. I learned the hard way…I had all of the wires through the brace bracket, wired up are ready and then realized….whoops!

The decorative white face plate will cover the metal plate.

This is what you do when you don’t have an extra set of hands. I put my barstool on the counter and put the basket on top of that to balance the light fixture. I had already determined how long I wanted the fixture to hang, marked it on the wire and secured on the fixture’s face plate.

Now it’s time to attach the wires to the 'socket pig tail'. Ground goes to ground and put a wire nut on it, those are the two exposed copper wires.

I had a tough time determining which wire was hot and a which wire was neutral. It was easy on the ‘pig-tail’ because black wire is always hot and white wire is always neutral. But on the light fixture, both wires were clear.

I had to look online to figure out which one was hot and which one was neutral. One wire had ridges or ribbing down one side. The other wire had super tiny white writing on it. You have to look carefully! I practically needed a magnifying glass to see the writing.

This is what I found out. Ridges or ribbing on the the one wire indicate neutral. The white writing indicates that wire is hot. To me that makes no sense…. wouldn’t you think that white writing would go with the white wire?? Ugh! Anyway, I checked it over and over to make sure I was connecting the correct wires together.

Ridges/ribbing = Neutral (WHITE) White writing = Hot (BLACK)

I think I got it!!

Twist the wires together and wirenut them. Then push all of the excess wires up and out of the way.

We are almost done!! Center the white plastic cover, align the fixture face plate and screw on the little knobs.

Voile’! Done!! And it WORKS!! Yay!!

Here's the little surprise! I couldn’t stand it white….So, I painted it!

Yep, orange! I love it orange!

Now, it’s definitely a little more me….

Blessings!!

very cool! Like the orange too, definitely unique as well. Thanks for some great ideas, trying to figure out what to do in my kitchen right now as far as lighting goes ;)

ReplyDelete